An energy system design workflow with simercator

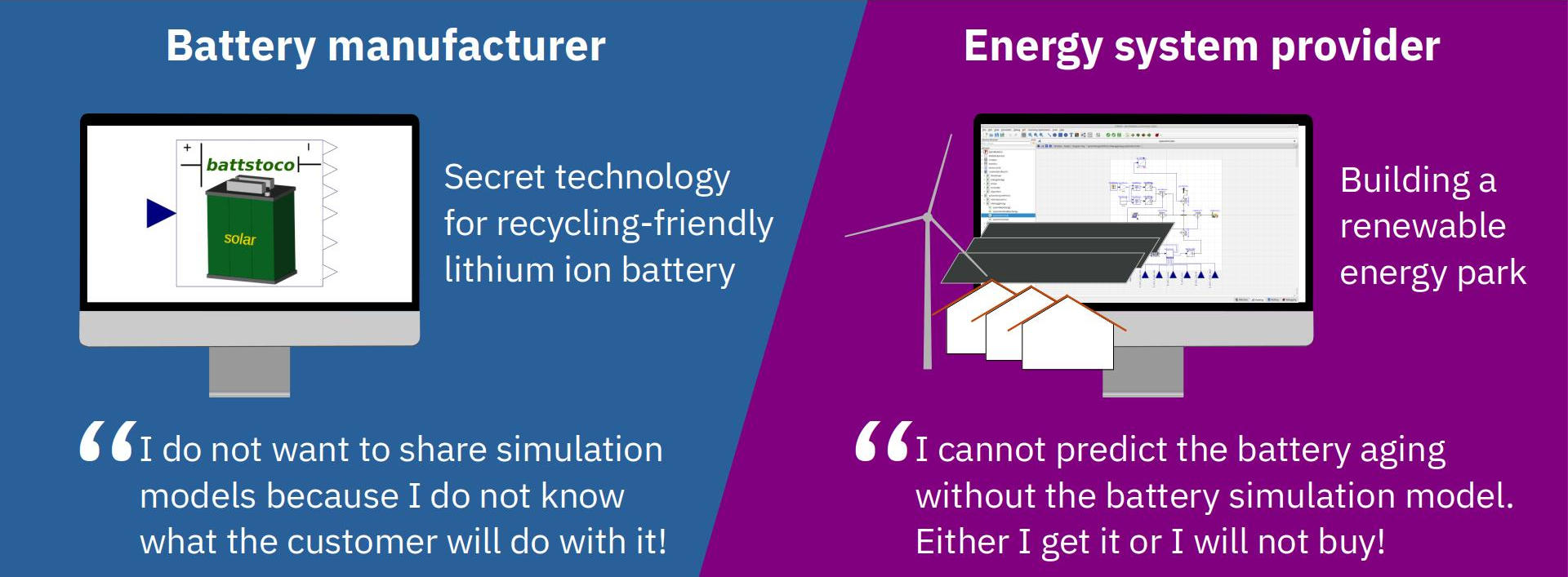

In this example we highlight a typical use case of simercator: Enabling battery manufacturers and energy system providers to exchange battery simulation models in a secure and fast way.

Simulation models for selecting technology and supplier

In this example, an energy system provider has to establish a renewable energy park with a battery storage. One of their system engineers has already set up a power flow simulation in a system simulation tool, but has not yet chosen a battery. The main simulation question is: How will a battery affect the electricity cost for the community?

Suppose the system engineer has found a potential candidate from an innovative battery manufacturer with a highly competitive initial buying price. However, this battery technology comes with a very difficult cyclic aging behavior.

This makes the simulation task very difficult: The other major cost driver for the battery besides the buying price is its depreciation due to aging. Which in turn depends on how the battery is actually being used. Therefore, the system engineer needs an accurate battery simulation model.

Keeping vs. sharing?

Battery manufacturers are often reluctant to share simulation models.

Their main concerns on battery simulation models are that

- without control over their usage the models may be used to reverse-engineer the battery technology or

- customers could accidentally use the models well outside the range in which they deliver accurate predictions.

Today, this would be solved by individual negotiations regarding non-disclosure and usage rights, before a simulation model would finally be provided via e-mail or a file share. Meanwhile, the system engineer’s work on the customer side would come to a halt, for days or maybe even weeks.

With simercator: Keeping and sharing

Using a simercator instance, the battery manufacturer can make a simulation model available without the need to actually distribute the model.

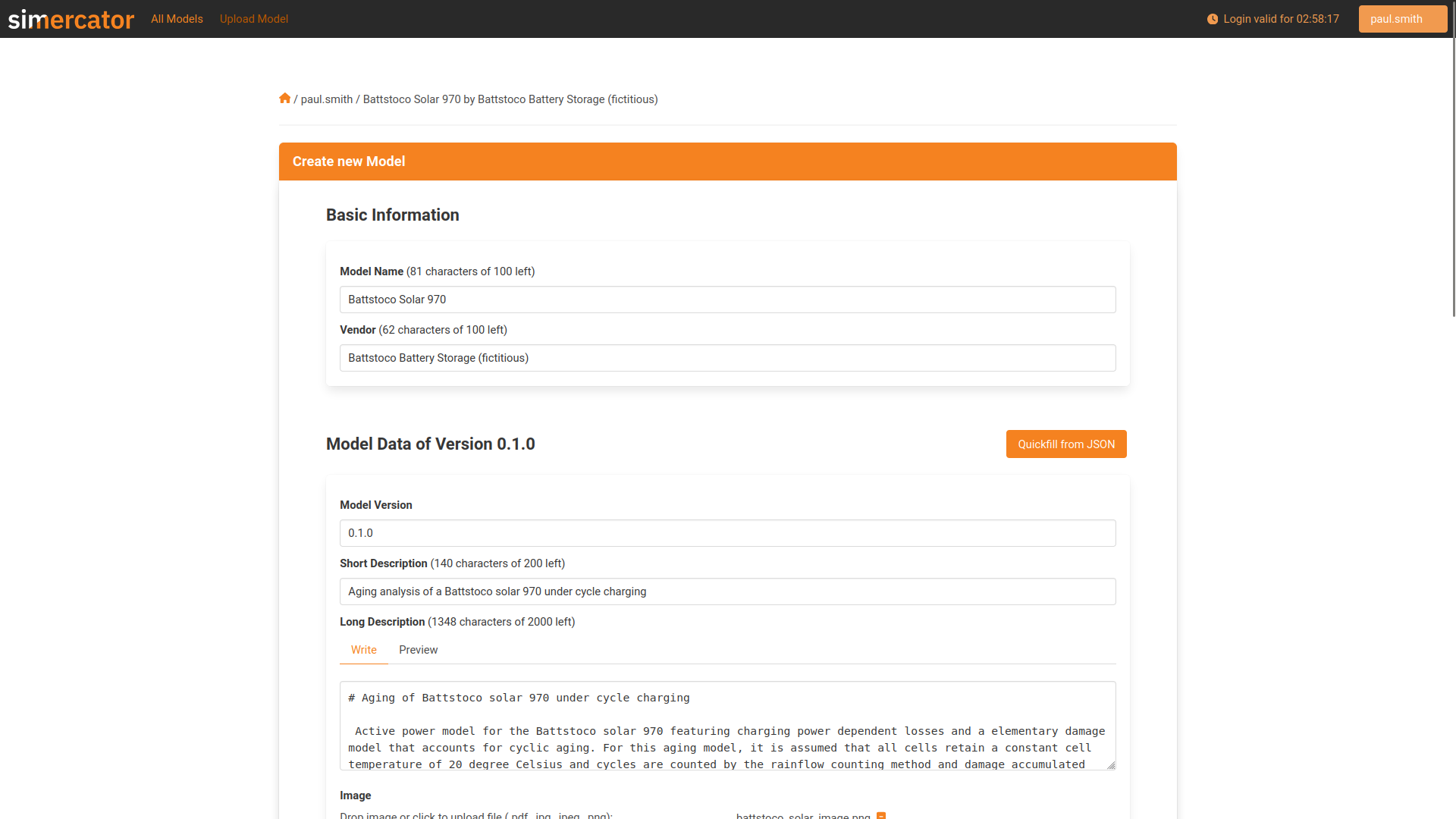

Getting models into simercator

To make a battery simulation model available through simercator is easy. All the battery manufacturer has to do is simply wrapping his existing model with simercator’s Python module (non-invasive!) into mostly just a single Python file. Then upload the model and its wrapper to the simercator instance. A web user interface including input, output and result visualizations is generated automatically. Now, a system engineer on the customer side can evaluate the model directly in the browser or download a hollow model clone (a doppelgaenger).

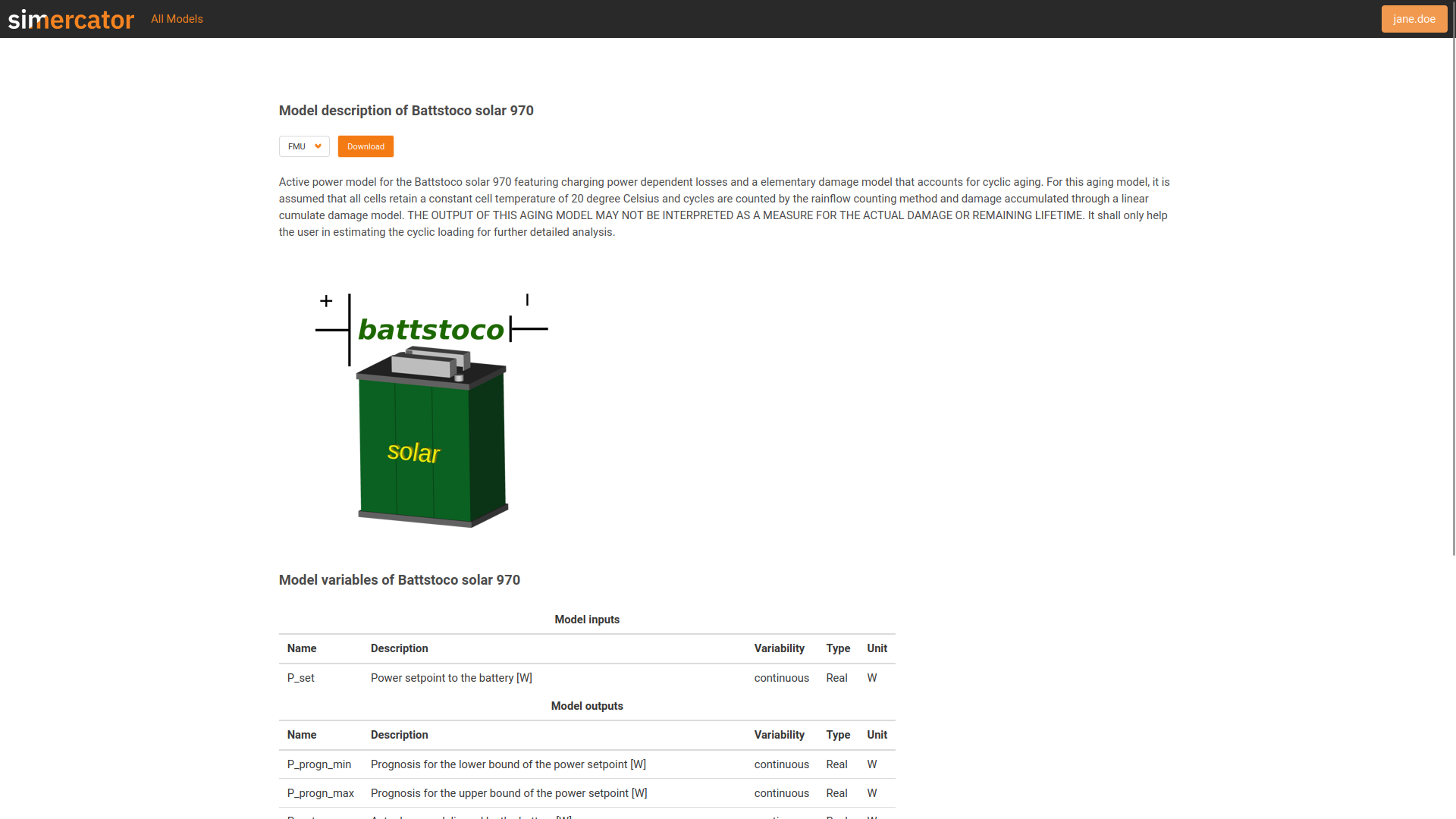

Evaluation in browser

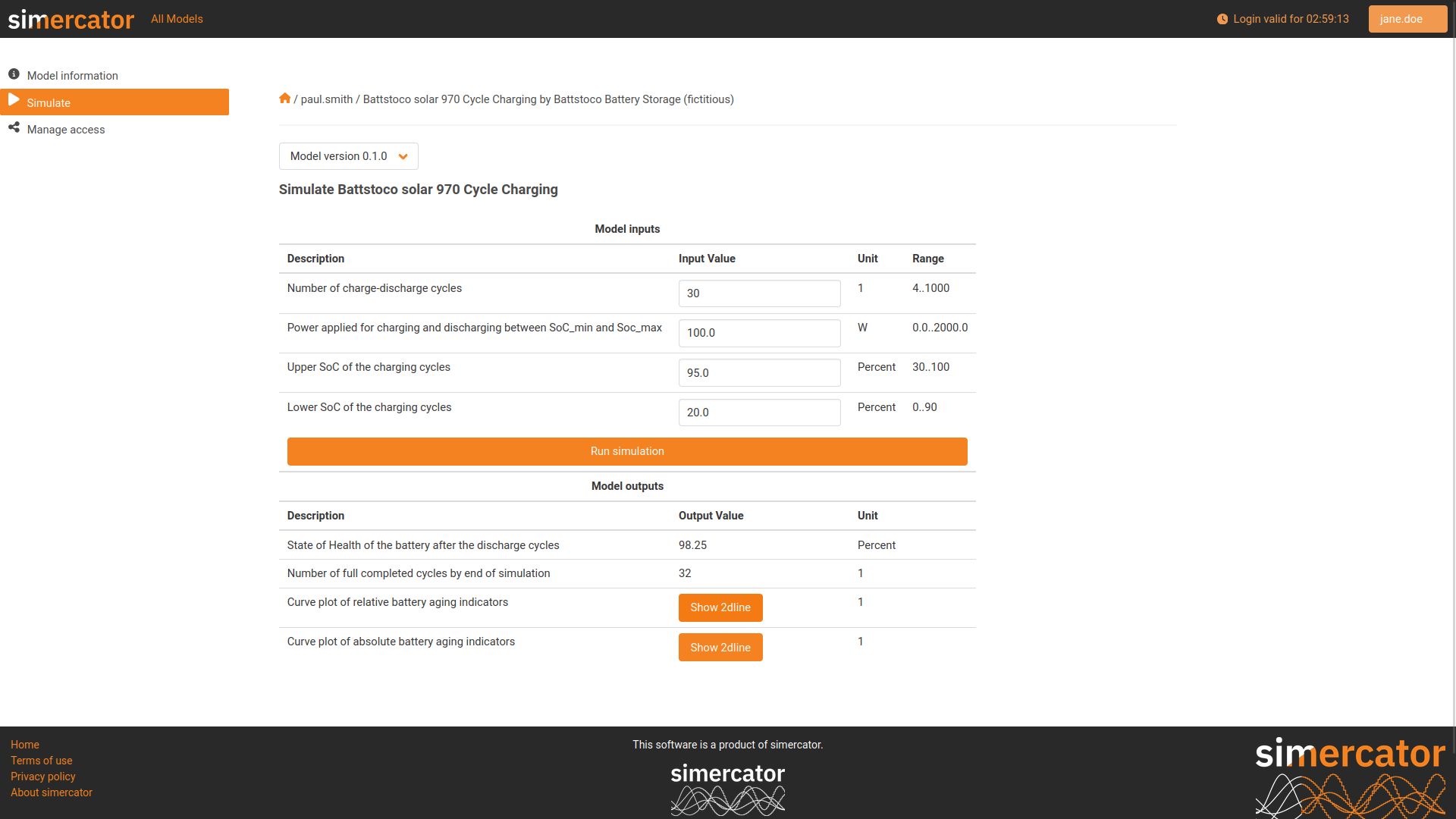

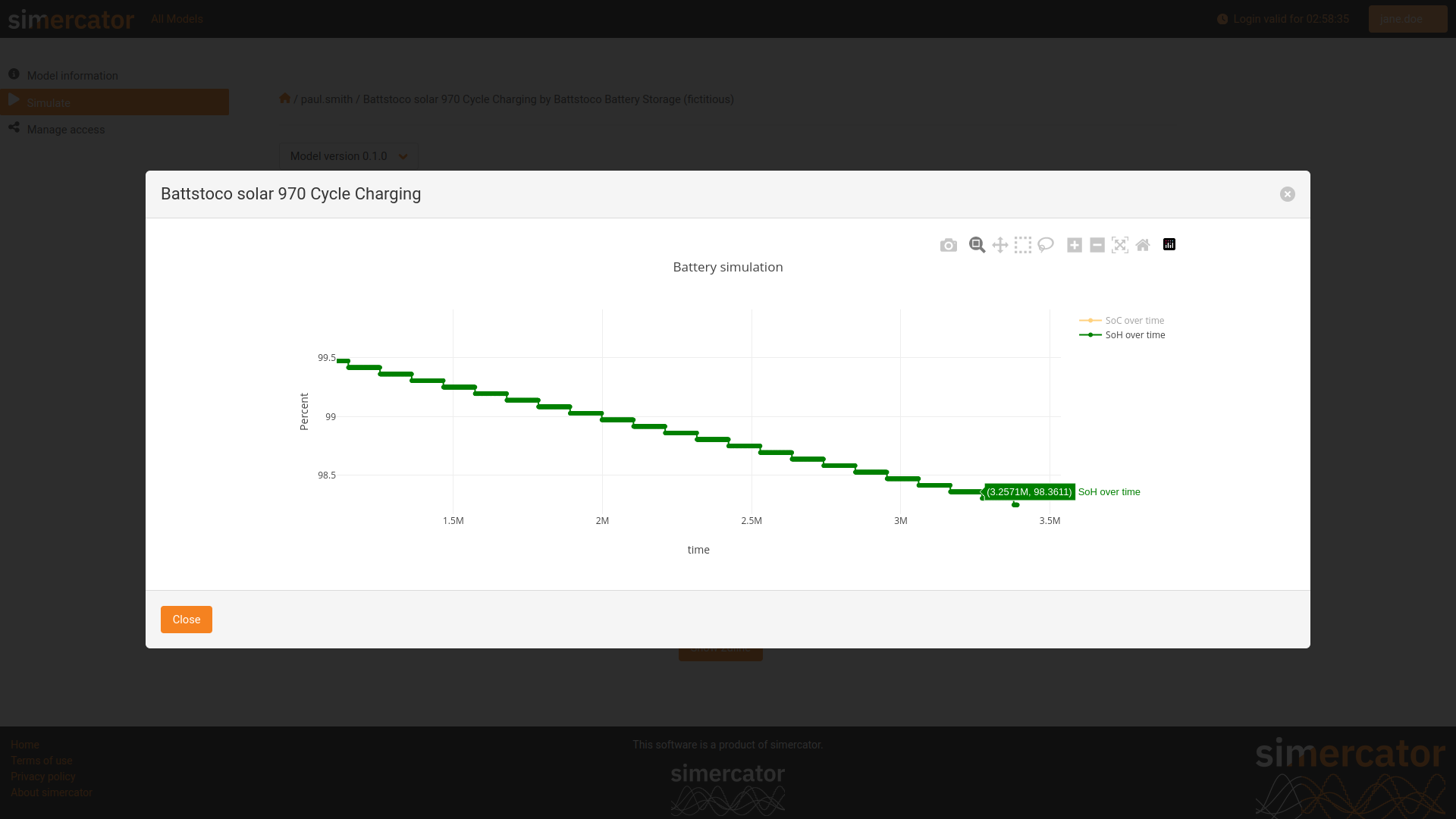

With an account for the simercator instance and rights to view and simulate the model, the system engineer can perform first quantitative evaluations in the browser, like computing the aging resulting from different cycle depths or charging powers.

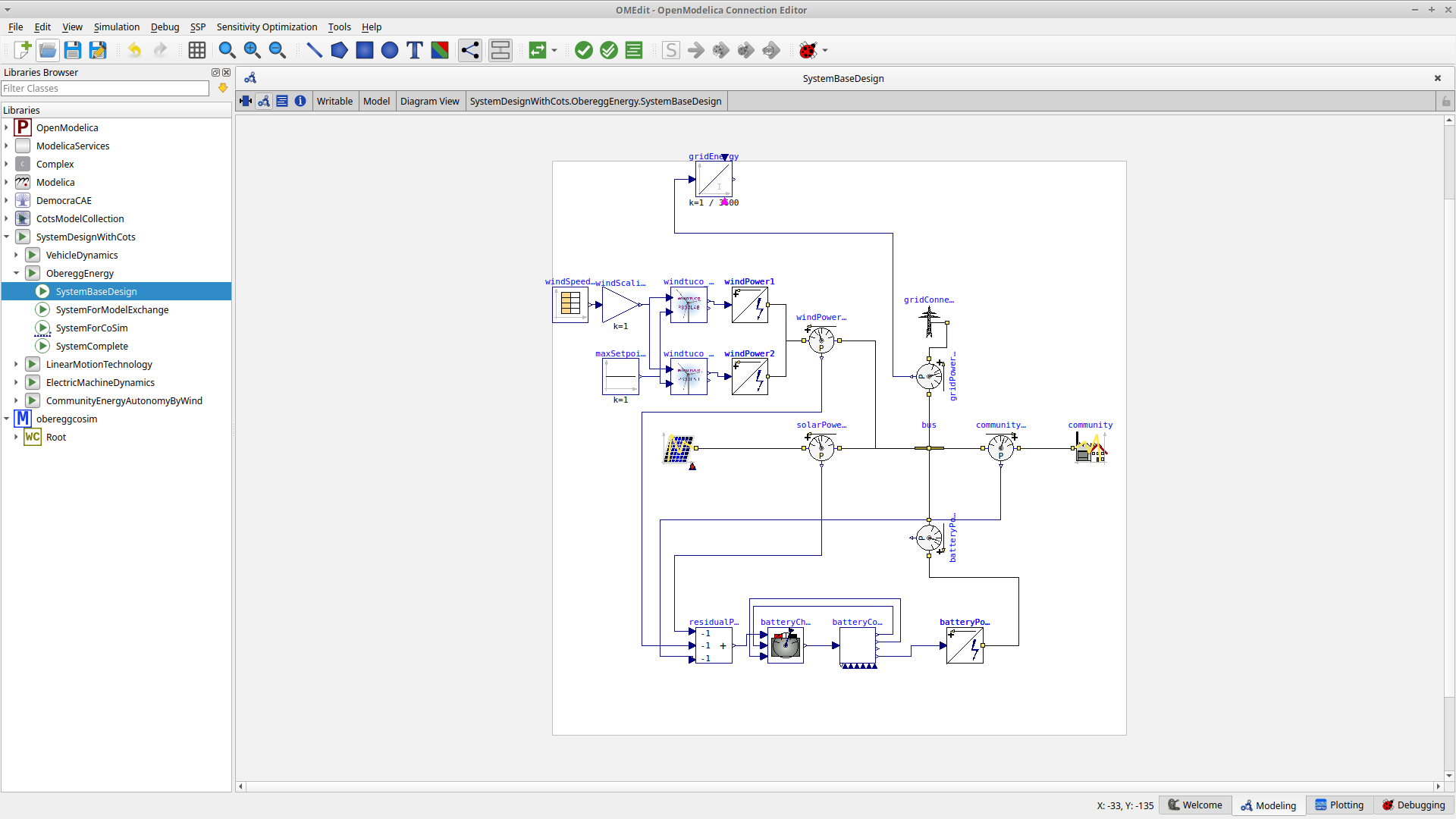

Download of a model doppelgaenger for system simulation

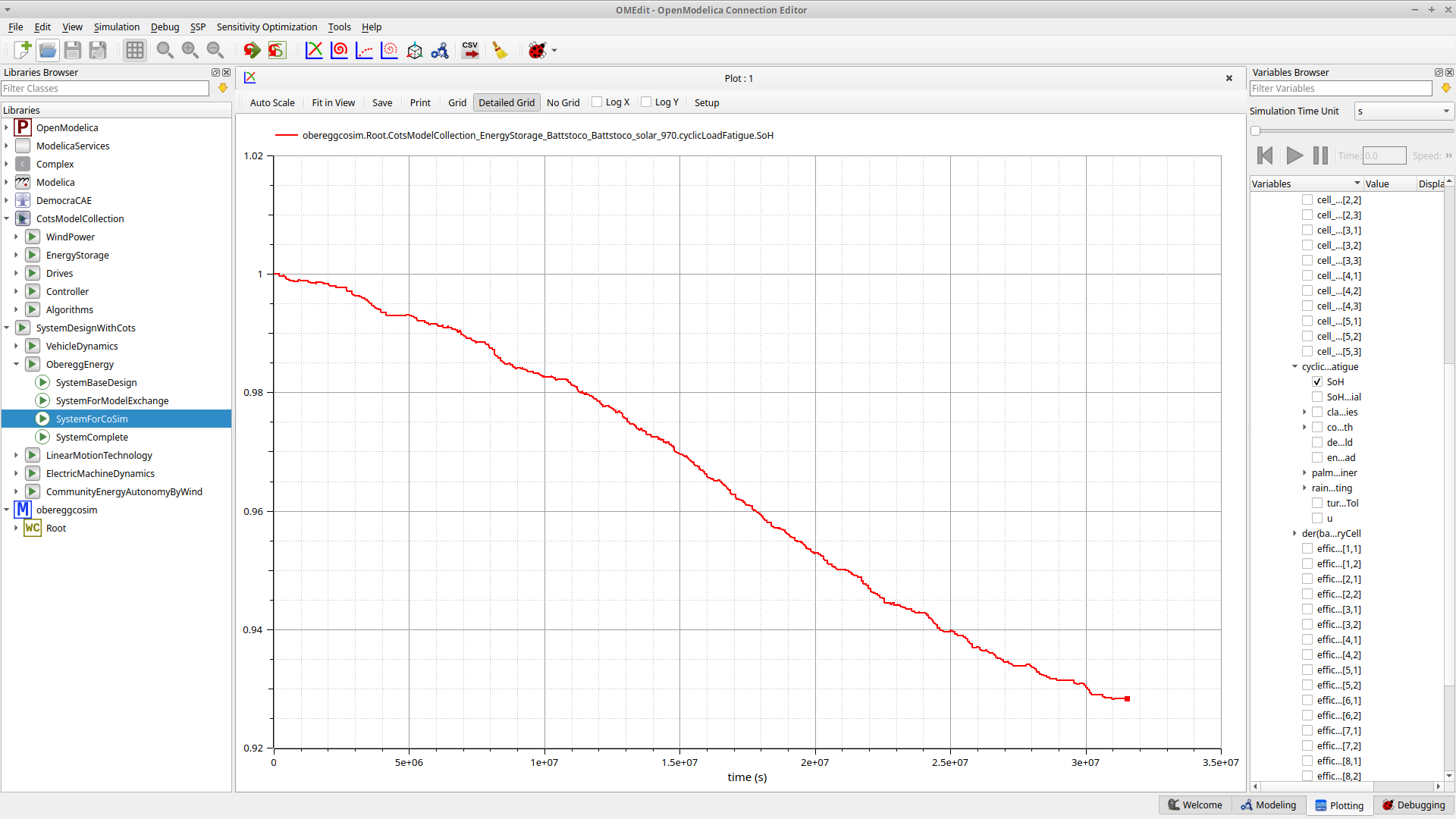

The system engineer can also download what we call in simercator a doppelgaenger of the original battery simulation model. A doppelgaenger is basically a hollow clone of the original model with the same inputs and outputs but without the original model’s inner workings. However, the system engineer can use this doppelgaenger in his/her own local system simulation tool to analyze its performance in the target system (here: the energy park), just as it were the original model. A Modelica tool, Simulink or any other software supporting the industry standard FMI for exchanging simulation models can be used.

With the doppelgaenger, the original model remains safely on the server of the simercator instance. Every time the system engineer performs an analysis with his/her simulation tool, the downloaded doppelgaenger would instantiate a communication with the simercator server, where the original model is evaluated during simulation.

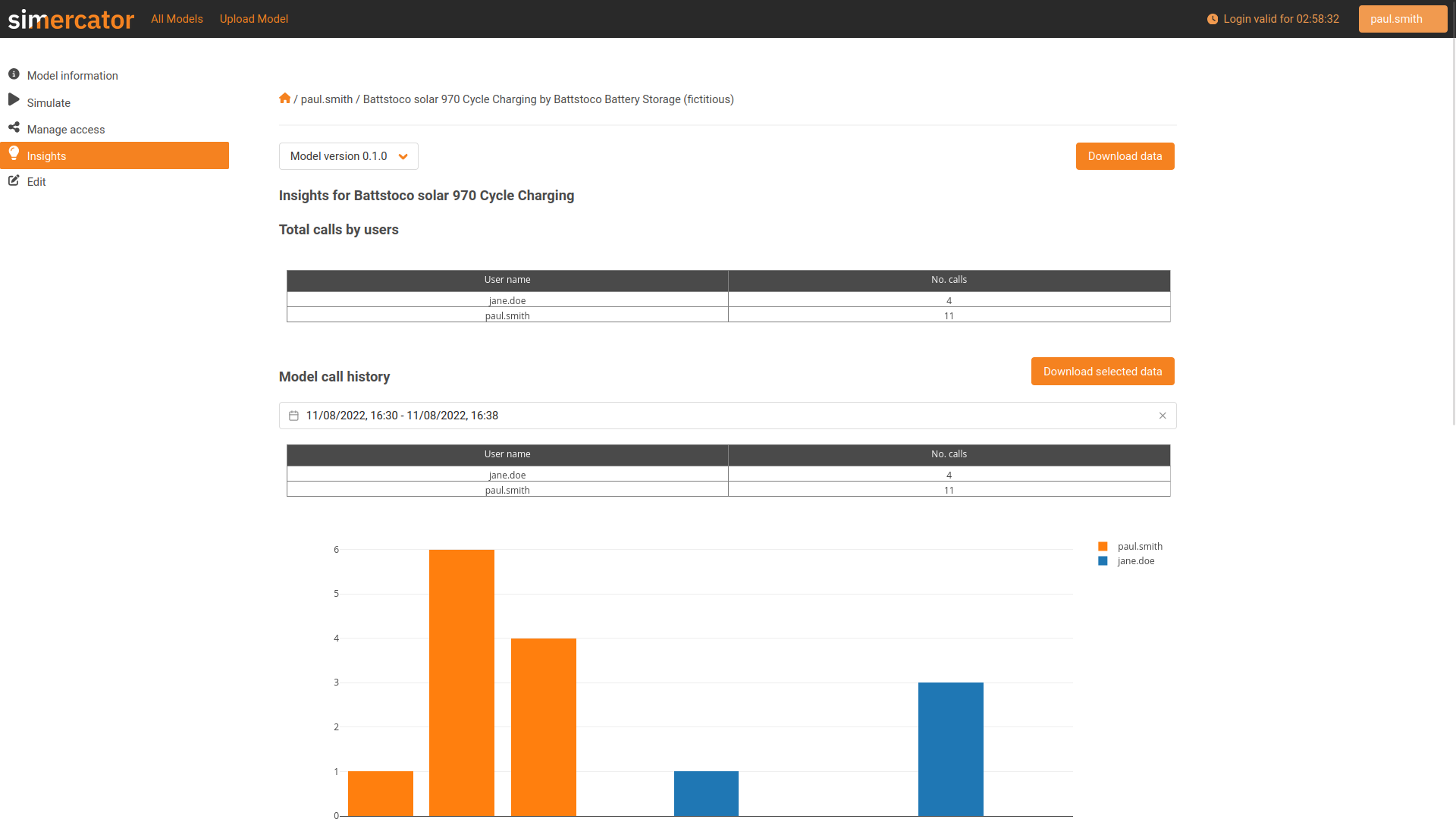

Data analytics

With simercator’s integrated data analytics the battery manufacturer can analyze the simulation requests of a “statistical user” in order to better understand requirements to the battery and also to support system engineers with the customer in using the simulation model.

Conclusion: Win-win when sharing simulation models with simercator

By using simercator to provide battery simulation models, battery manufacturers increase the value of their products for their customers because they save their customers valuable engineering time. In this fashion, their customers achieve shorter development cycles with better simulation quality, while battery manufacturers get a quantitative understanding of future requirements to their products.